These tables are often designed for casting large panels in a horizontal position and can tilt to facilitate the removal of the panels after curing. The tilting function helps in lifting the panel out of the mold without damaging it.

The hot water heating system would be used to accelerate the curing process by maintaining a higher temperature, which is crucial for quick turnaround in precast production. By running hot water through channels in the table, the concrete can cure faster, improving overall efficiency.

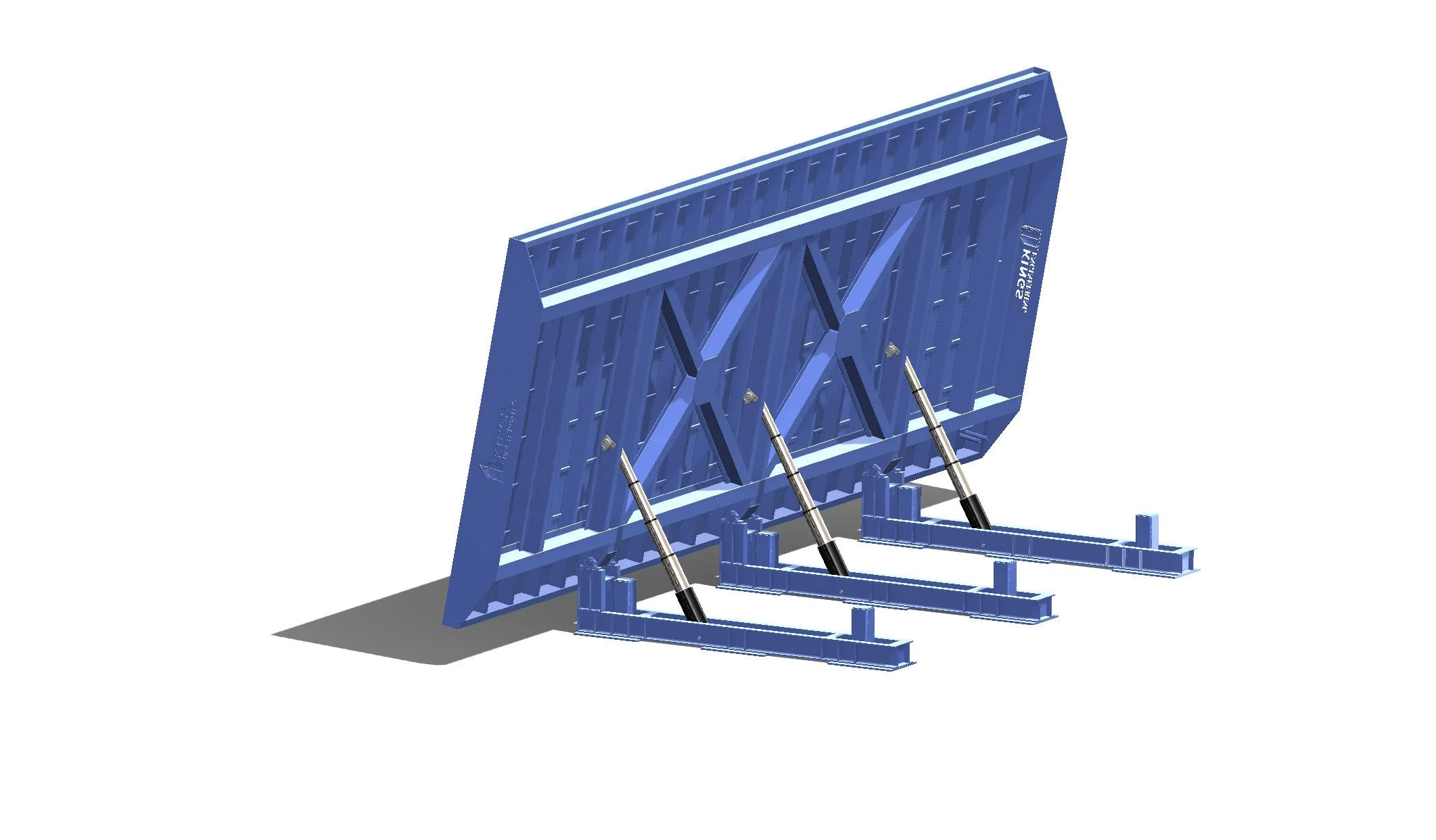

Hydraulic Tilting: The table can tilt to a near-vertical position to easily demold the panel. Hydraulic cylinders or screw jacks are commonly used to provide the tilting force.

Safety Features: Kings Engineering heated tables includes limit switches and locking mechanisms to ensure safe operation during the tilting process.

Automation: In modern facilities, the entire process can be automated, from pouring concrete to heating and tilting the table.

These tables are often designed for casting large panels in a horizontal position and can tilt to facilitate the removal of the panels after curing. The tilting function helps in lifting the panel out of the mold without damaging it.

The hot water heating system would be used to accelerate the curing process by maintaining a higher temperature, which is crucial for quick turnaround in precast production. By running hot water through channels in the table, the concrete can cure faster, improving overall efficiency.

Hydraulic Tilting: The table can tilt to a near-vertical position to easily demold the panel. Hydraulic cylinders or screw jacks are commonly used to provide the tilting force.

Safety Features: Kings Engineering heated tables includes limit switches and locking mechanisms to ensure safe operation during the tilting process.

Automation: In modern facilities, the entire process can be automated, from pouring concrete to heating and tilting the table.